In any workshop, whether it be for woodworking, metalworking, or general manufacturing, securing workpieces efficiently and securely is critical for achieving precision and safety. Magnetic fixture clamps have become an indispensable tool for many professionals due to their strong holding power, versatility, and ease of use. This post will guide you through the process of choosing the right magnetic fixture clamp for your workshop, discussing the key features, types, and applications to ensure you make an informed decision.

What are Magnetic Fixture Clamps?

Magnetic fixture clamps, also known as magnetic clamps or magnetic work-holding clamps, use magnetic force to secure workpieces in place. These clamps offer several advantages over traditional mechanical clamps, including quick setup, uniform holding force, and the ability to hold irregularly shaped or delicate workpieces without causing damage.

Key Features to Consider

When selecting a magnetic fixture clamp for your workshop, it’s essential to consider several key features to ensure you choose the best tool for your specific needs:

1. Holding Force

The holding force of a magnetic fixture clamp is one of the most critical factors to consider. It determines how securely the clamp can hold the workpiece in place. Clamps with higher holding forces are suitable for heavy-duty applications and larger workpieces, while lower holding forces may be sufficient for lighter tasks.

2. Material Compatibility

Ensure that the magnetic fixture clamp you choose is compatible with the materials you work with. Most magnetic clamps are designed for use with ferrous metals (iron, steel, etc.), but some advanced models can also work with non-ferrous materials.

3. Adjustability

Adjustability is an important feature of versatility. Look for clamps that allow for easy adjustment of the magnetic force and positioning. This flexibility will enable you to secure a wide range of workpieces with varying shapes and sizes.

4. Ease of Use

User-friendly design is crucial for efficient workflow. Choose magnetic fixture clamps that are easy to set up, operate, and release. Features like ergonomic handles and intuitive controls can significantly enhance usability.

5. Durability

Durability is essential for any workshop tool. Magnetic fixture clamps should be made from high-quality materials that can withstand regular use and harsh working conditions. Check for robust construction and resistance to wear and tear.

6. Safety Features

Safety should never be compromised. Look for clamps with built-in safety features such as secure locking mechanisms, fail-safes to prevent accidental release, and indicators to show the status of the magnetic force.

Types of Magnetic Fixture Clamps

Magnetic fixture clamps come in various types, each suited for different applications and requirements. Understanding the different types will help you select the right clamp for your specific tasks:

1. Permanent Magnetic Clamps

Permanent magnetic clamps use strong permanent magnets to hold workpieces. These clamps are reliable and do not require an external power source, making them suitable for a wide range of applications. However, they offer limited adjustability in terms of magnetic force.

2. Electromagnetic Clamps

Electromagnetic clamps use an electric current to generate a magnetic field. These clamps offer greater control over the holding force, allowing for precise adjustments. They are ideal for applications where variable holding power is needed. However, they require a continuous power supply to maintain the magnetic force.

3. Electro-Permanent Magnetic Clamps

Electro-permanent magnetic clamps combine the advantages of both permanent and electromagnetic clamps. They use an initial electric pulse to magnetize or demagnetize the clamp, providing adjustable holding force without requiring a constant power supply. These clamps are highly versatile and energy-efficient.

4. Magnetic V-Blocks

Magnetic V-blocks are specialized clamps designed to hold cylindrical or round workpieces. They have a V-shaped groove and magnetic force to securely hold the workpiece in place. These clamps are commonly used in machining and inspection tasks.

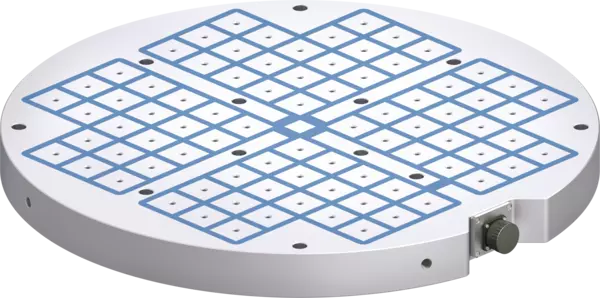

5. Magnetic Chucks

Magnetic chucks are large, flat magnetic clamps used in machining and grinding operations. They provide a stable and secure work-holding surface for flat or irregularly shaped workpieces. Magnetic chucks are often used on milling machines, surface grinders, and lathes.

Applications of Magnetic Fixture Clamps

Magnetic fixture clamps are versatile tools used in various applications across different industries. Here are some common applications:

1. Machining and Milling

In machining and milling operations, magnetic fixture clamps provide secure work holding for accurate cutting, drilling, and milling. They are particularly useful for holding irregularly shaped or thin workpieces that may be challenging to secure with traditional clamps.

2. Welding and Fabrication

Magnetic fixture clamps are widely used in welding and fabrication tasks to hold metal pieces in place during welding. They offer quick setup and strong holding force, ensuring precise alignment and reducing setup time.

3. Assembly and Inspection

In assembly and inspection processes, magnetic fixture clamps provide a stable platform for holding components and workpieces. They facilitate accurate alignment and inspection, improving overall efficiency and quality control.

4. Woodworking

Magnetic fixture clamps are also used in woodworking for holding metal parts or tools during woodworking tasks. They offer a convenient and secure way to keep metal components in place without damaging the wood.

5. Automotive and Aerospace

In the automotive and aerospace industries, magnetic fixture clamps are used for various tasks, including engine assembly, component testing, and inspection. Their strong holding force and precision make them ideal for these high-stakes applications.

Tips for Choosing the Right Magnetic Fixture Clamp

To choose the right magnetic fixture clamp for your workshop, consider the following tips:

1. Assess Your Needs

Start by assessing your specific needs and applications. Determine the types of workpieces you will be holding, the required holding force, and any special features you may need.

2. Research and Compare

Research different types of magnetic fixture clamps and compare their features, advantages, and limitations. Consider reading reviews and seeking recommendations from industry professionals.

3. Consider Quality and Brand Reputation

Choose magnetic fixture clamps from reputable brands known for their quality and reliability. Investing in high-quality clamps will ensure long-term performance and safety.

4. Evaluate Adjustability and Versatility

Select clamps that offer adjustability and versatility to accommodate a wide range of workpieces and tasks. Adjustable magnetic force and flexible positioning can enhance the usability of the clamps.

5. Prioritize Safety

Ensure that the clamps you choose have adequate safety features to prevent accidents and ensure secure work holding. Safety should always be a top priority in any workshop.

6. Consult with Experts

If you are unsure about which magnetic fixture clamp to choose, consider consulting with experts or suppliers who can provide guidance based on your specific requirements.

Conclusion

Choosing the right magnetic fixture clamp for your workshop is essential for achieving precision, efficiency, and safety in your work-holding tasks. By considering key features such as holding force, material compatibility, adjustability, ease of use, durability, and safety, you can make an informed decision that meets your needs.

For high-quality magnetic fixture clamps, Schunk offers a comprehensive range of products designed to meet diverse requirements. With their expertise and commitment to innovation, Schunk provides reliable and precise work-holding solutions that cater to various industrial and workshop applications. Whether you need permanent, electromagnetic, or electro-permanent magnetic clamps, Schunk has the right solution to enhance your workshop’s productivity and performance.

Feel free to submit more guest posts through Links Building Servcies - Best Prices. Buy Author Account / 1$ Guest Post Here